OTR Tire-School

Basic knowledge of Over The Road Tires

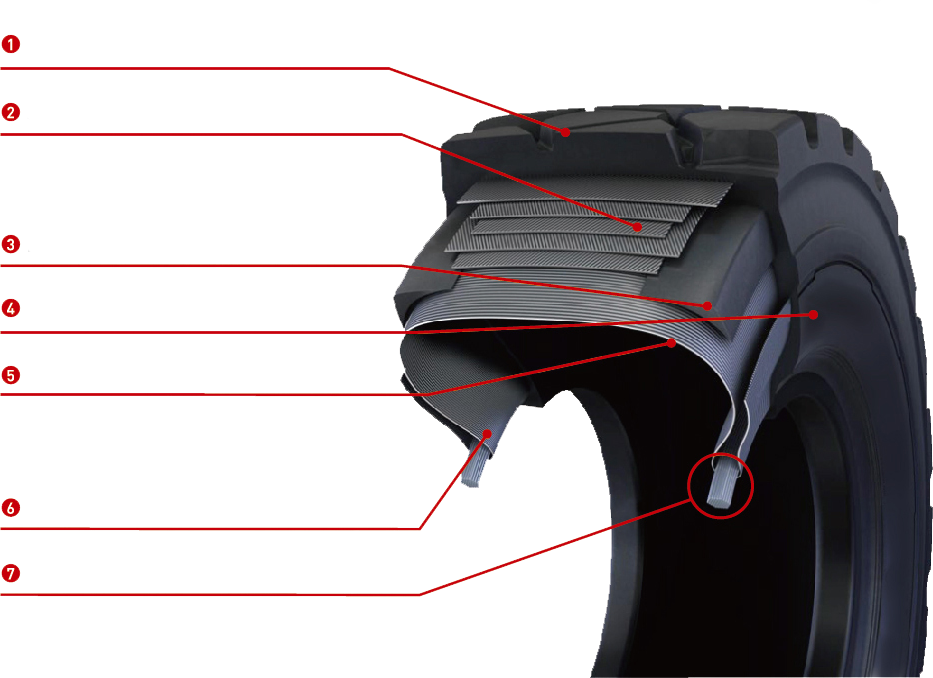

Radial Construction

- Tread

- Steelcord Belts

- Belt Cushion

- Sidewall

- Steelcord carcass

- innerliner

- Apex, Chafer, Bead and wire cores

1. Tread

This wear-resistant rubber protects carcass and belt against fractures and impacts.

This wear-resistant rubber protects carcass and belt against fractures and impacts.

2. Steelcord Belt

The belts are layers of steel cord located between the tread and the body ply. The belts increase the rigidity of the tread, increasing the tire’s resistance to cuts. They also transmit the torque to the radial ply and restrict tire growth.

The belts are layers of steel cord located between the tread and the body ply. The belts increase the rigidity of the tread, increasing the tire’s resistance to cuts. They also transmit the torque to the radial ply and restrict tire growth.

3. Belt cushion

This component reduces temperature generation.

This component reduces temperature generation.

4. Sidewall

The sidewall is a protective rubber coating on the outer side of the tire. It is designed to resist cutting. scuffing and cracking.

The sidewall is a protective rubber coating on the outer side of the tire. It is designed to resist cutting. scuffing and cracking.

5. Steelcord carcass

The carcass acts to support air pressure and absorb shocks. It consists of steel-ply and has high strength to ensure structural durability combined with high flexibility, very good damping and rolling resistance.

The carcass acts to support air pressure and absorb shocks. It consists of steel-ply and has high strength to ensure structural durability combined with high flexibility, very good damping and rolling resistance.

In a radial construction, steel carcass material runs directly from bead to bead (radial) and the tread is stabilized by steel belt, while sidewall and tread function independently. The shocks absorbed by the sidewall will not be shifted to the tread, therefore the deformation of contact patch is minimized.

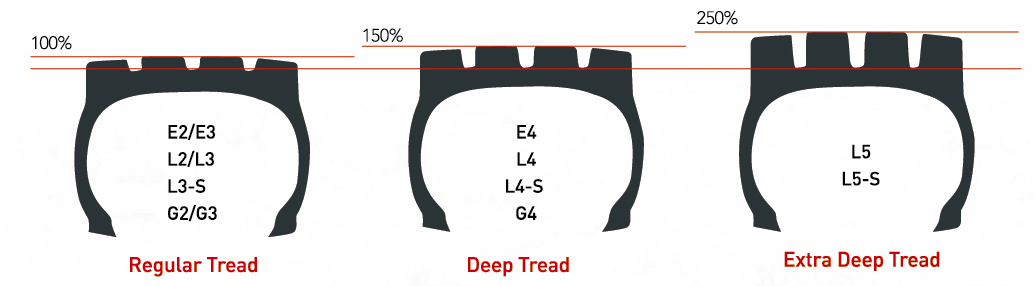

Usage Indication (Pattern Design & Tread Depth)

The combination of the letters and numbers is often called TRA-or EM-Code and is an international categorization for OTR tires. The following table exhibits an overview of the different combinations.

In accordance with : ETRTO, TRA, JATMA and ISO

Can’t Find what you need ?